What Is Backflow?

Backflow happens when water flows opposite to its intended path within a plumbing system. This situation can lead to the contamination of clean water supplies, potentially causing illness or exposure to harmful substances. It often occurs when there’s a sudden drop in water pressure or when pressure imbalances develop between different areas of a water system.

Backflow prevention is crucial in ensuring that harmful substances do not mix with clean drinking water, and one of the key strategies to prevent it is using backflow prevention devices.

Dangers of Backflow

Backflow is dangerous because it can lead to the contamination of potable water. When backflow occurs, water from external sources, such as irrigation systems, pools, or chemical-laden industrial systems, can be siphoned back into clean water supplies.

Backflow is dangerous because it can lead to the contamination of potable water. When backflow occurs, water from external sources, such as irrigation systems, pools, or chemical-laden industrial systems, can be siphoned back into clean water supplies.

This contaminated water may carry:

- Hazardous chemicals

- Pesticides

- Bacteria

- Groundwater

- Human or industrial waste

Backflow can happen through two main mechanisms: backpressure and back siphonage. Backpressure occurs when there is an increase in pressure on the non-potable side of a plumbing system, causing water to flow back into the clean side.

Back siphonage happens when a drop in water pressure on the clean water side, such as from a main water line break or heavy demand on the system, pulls the water back from potentially contaminated sources.

These scenarios illustrate why backflow prevention devices are required by law in many regions and are essential to public health and safety.

Testing Backflow Prevention Devices

Backflow prevention strategies include the installation and inspection of different devices and construction methods. The simplest backflow prevention strategy includes an air gap between a freshwater source and potential contamination.

Backflow prevention strategies include the installation and inspection of different devices and construction methods. The simplest backflow prevention strategy includes an air gap between a freshwater source and potential contamination.

These are found around the home in water heater overflow piping and HVAC condensate lines. Air gaps must be installed and inspected according to codes, but they don’t require further inspection.

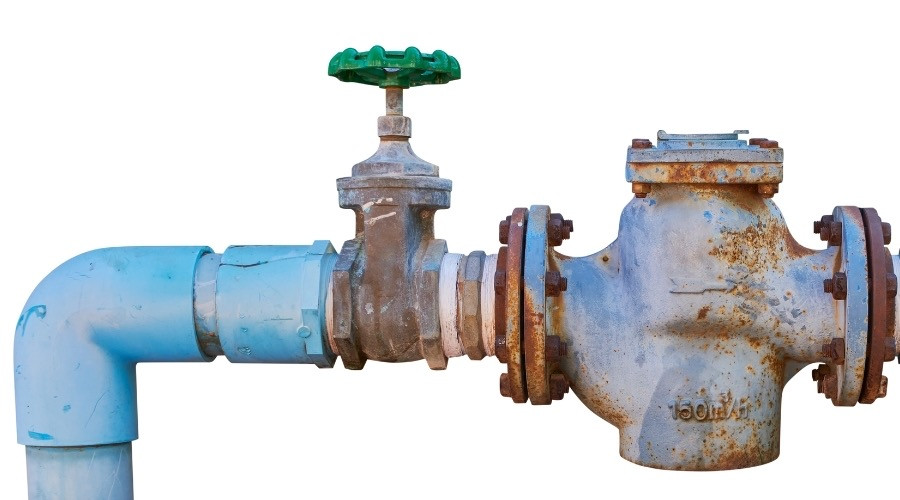

The second backflow prevention strategy involves mechanical devices called backflow preventers. These devices are necessary in situations where an air gap would be unsuitable. They use a series of pressure-controlled valves to raise the pressure inside the piping where backflow may occur. With slight changes in pressure on either side of the piping, check valves close and prevent backflow.

These devices are more complicated than air gaps and must be inspected on a schedule local authorities dictate. Most governing bodies require yearly inspection and certification by professionals, but backflow preventers in certain businesses, such as hospitals or industrial settings, may need more frequent certification.

Reasons for Backflow Testing

Backflow only occurs under abnormal circumstances, which is why freshwater supplies need to be constantly protected. The main reason for periodic backflow testing is to ensure the backflow preventers are always serviceable.

By inspecting them regularly, professionals can catch problems before they become disasters. If problems are found, they will be repaired quickly for continued protection.

By getting backflow preventers tested regularly, owners can ensure they do their part to protect local water resources. Backflow preventers are an asset to public health and prevent diseases and exposures to harmful pollutants by preventing backflow.

Always check with local authorities and partner with local plumbers to ensure the water in every home and business is safe.

About Master Plumbing, Heating, & Cooling

Master Plumbing, Heating, & Cooling protect water grids with high-quality installation practices and backflow testing. Their award-winning crews also handle HVAC and air quality concerns. Call today for safer and more reliable backflow testing in Cedar Rapids, IA.